Wireless Vibration Solutions Kit

Challenge

Knowing the condition of assets is critical to maintaining and improving productivity. Vibration monitoring and predictive maintenance of such assets require the ability to visualize data and understand information and then set intelligent thresholds for meaningful alarms. Typically, this can mean difficult programming or the need for in-depth vibration knowledge.

Banner Wireless Value

Visualize Data and Alarms—HMI clearly displays alarms and graphs of raw vibration data along with baseline, warning, and alarm values.

Simplicity—Plug in the box, bind nodes through the HMI screen, install sensors, and start collecting data. No programming is required.

Capability—Monitor vibration and temperature on up to 40 assets with wireless Nodes connected to VT1 vibration sensors.

Automatic Data Metrics—No need to manually set data baselines or thresholds.

Vibration Analytics—Fault indicators prior to major failures or disruptions by analyzing RMS Velocity and High-Frequency Acceleration on the X and Z axis.

Peel and Stick—Battery-powered Nodes attached to vibration sensors can mount virtually anywhere.

IIoT—Connect to network for remote monitoring via cloud services.

Productivity—Avoid unexpected downtime and be able to schedule repairs.

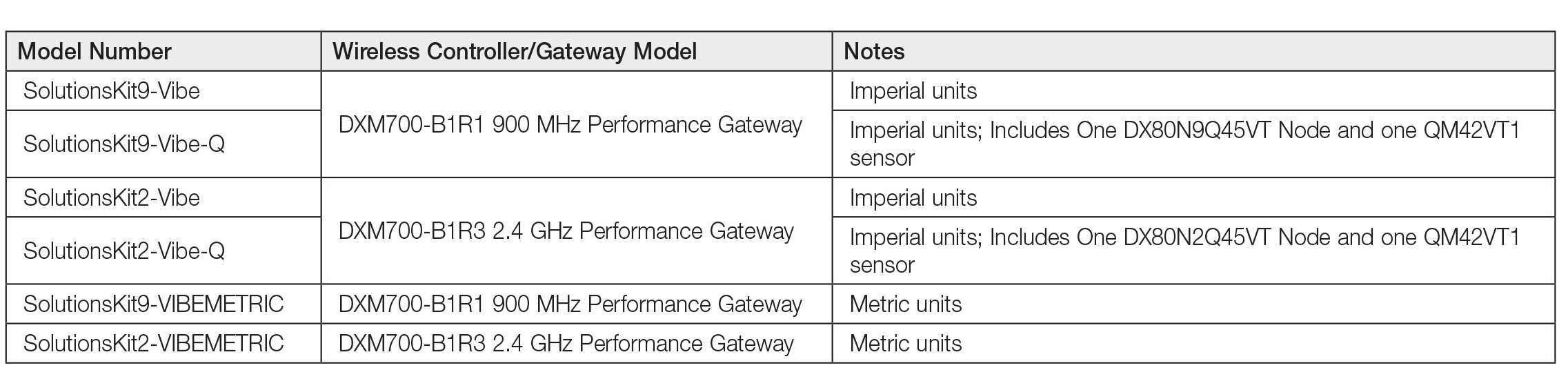

Banner Wireless Vibration Solutions Kit

Everything needed in one solution – Just add the Node/sensors as required

Pre-programmed DXM700 (using a unique version of the Vibration Monitoring & Predictive Maintenance Solutions Guide files)

Pre-programmed 10.1-inch touchscreen HMI for visualizing data

5-port Industrial Ethernet switch for network connection

View up to seven days of data history on the HMI while archiving over 30 days of logged data in CSV files on the HMI

Bind and perform site surveys of Nodes through the HMI

Create new asset baselines easily via the HMI

Add local indication of faults using optional DXM outputs to tower lights or indicator lights.

Use the Condition Monitoring Node to monitor vibration and current.

Key Applications

Monitor vibrations and current of any critical asset for predictive maintenance or need for full-spectrum analysis.

Identify abnormal asset conditions caused by misalignment, unbalance, bearing failures, pump cavitation, blade damage, etc.

Use on almost any asset such as motors, fans, compressors, pumps, etc.